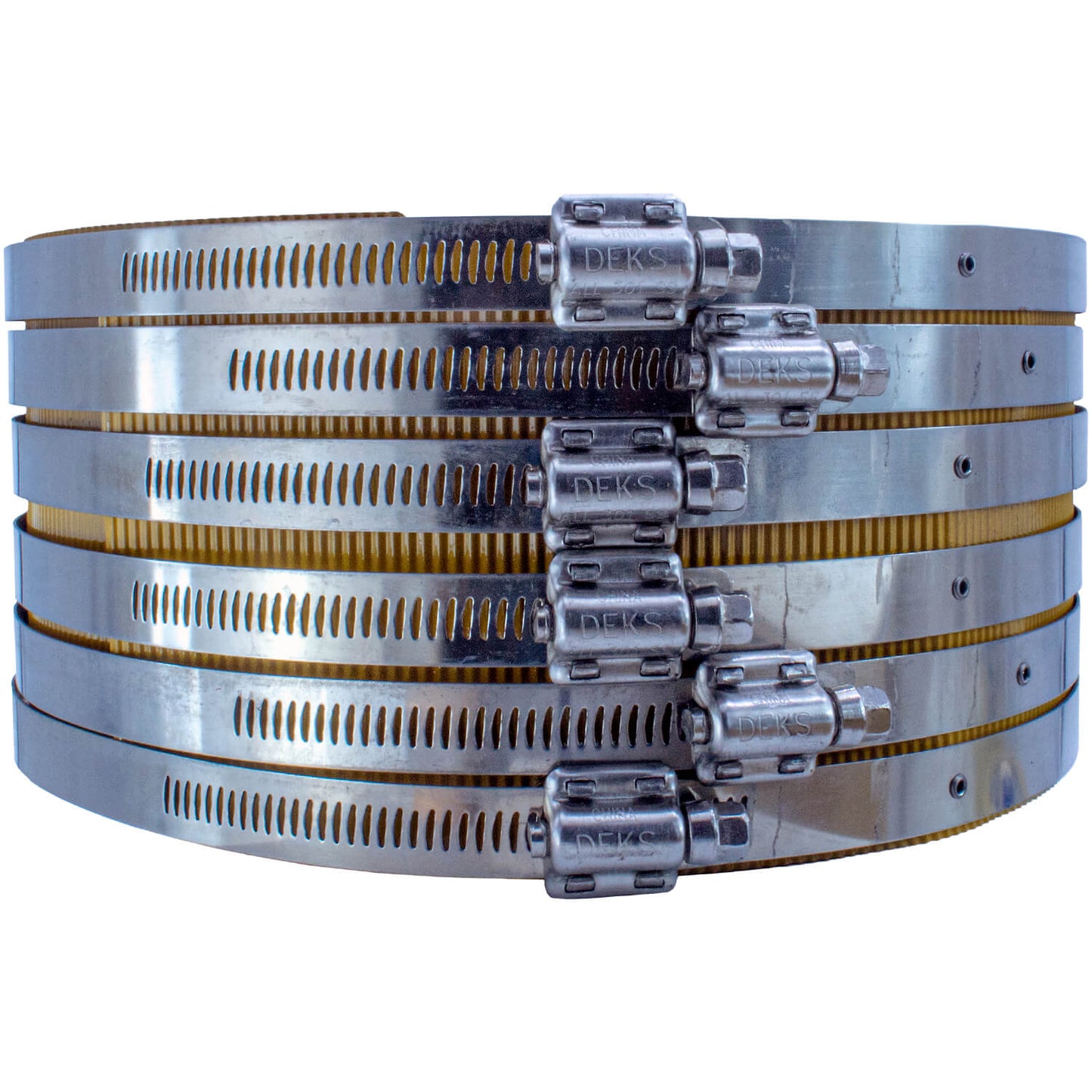

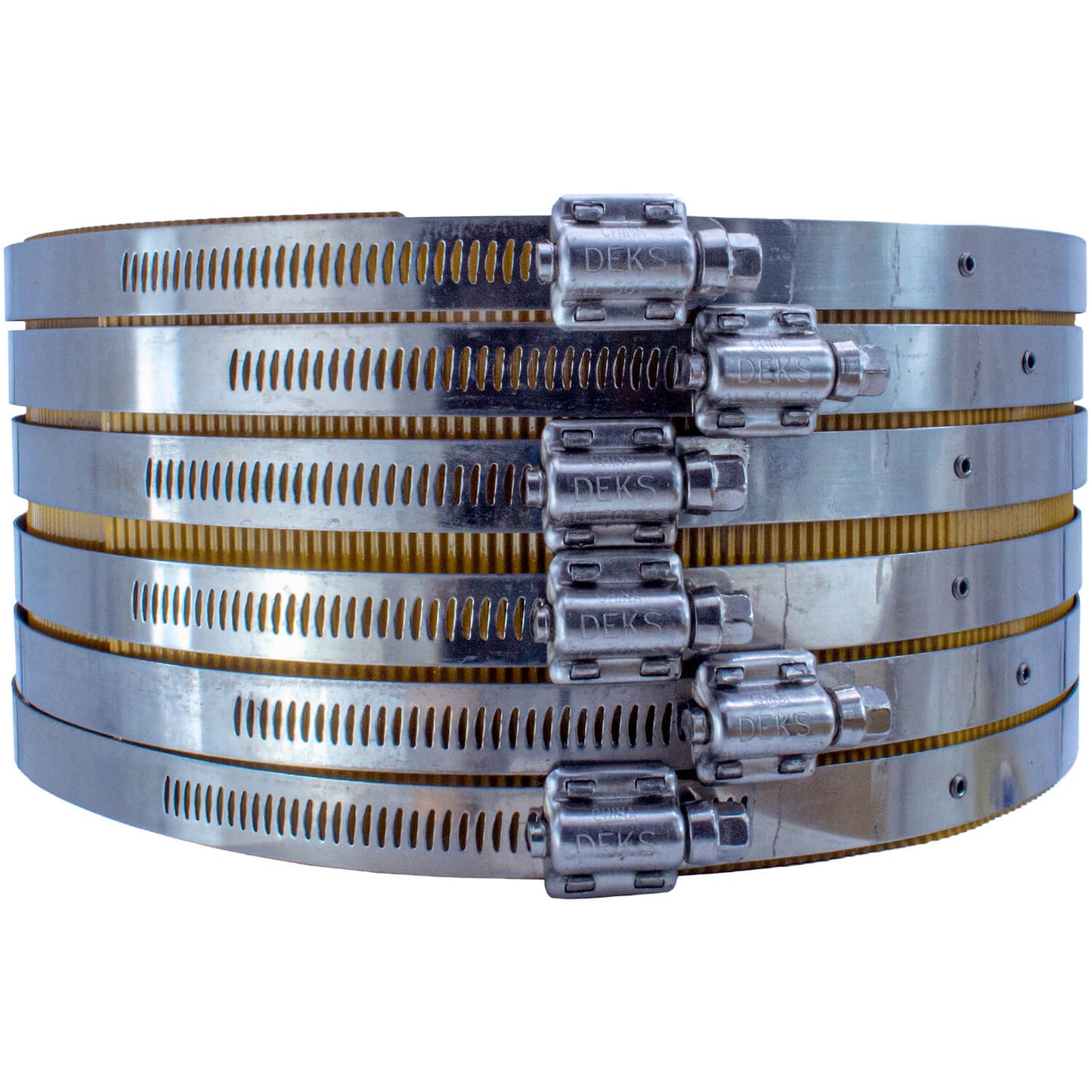

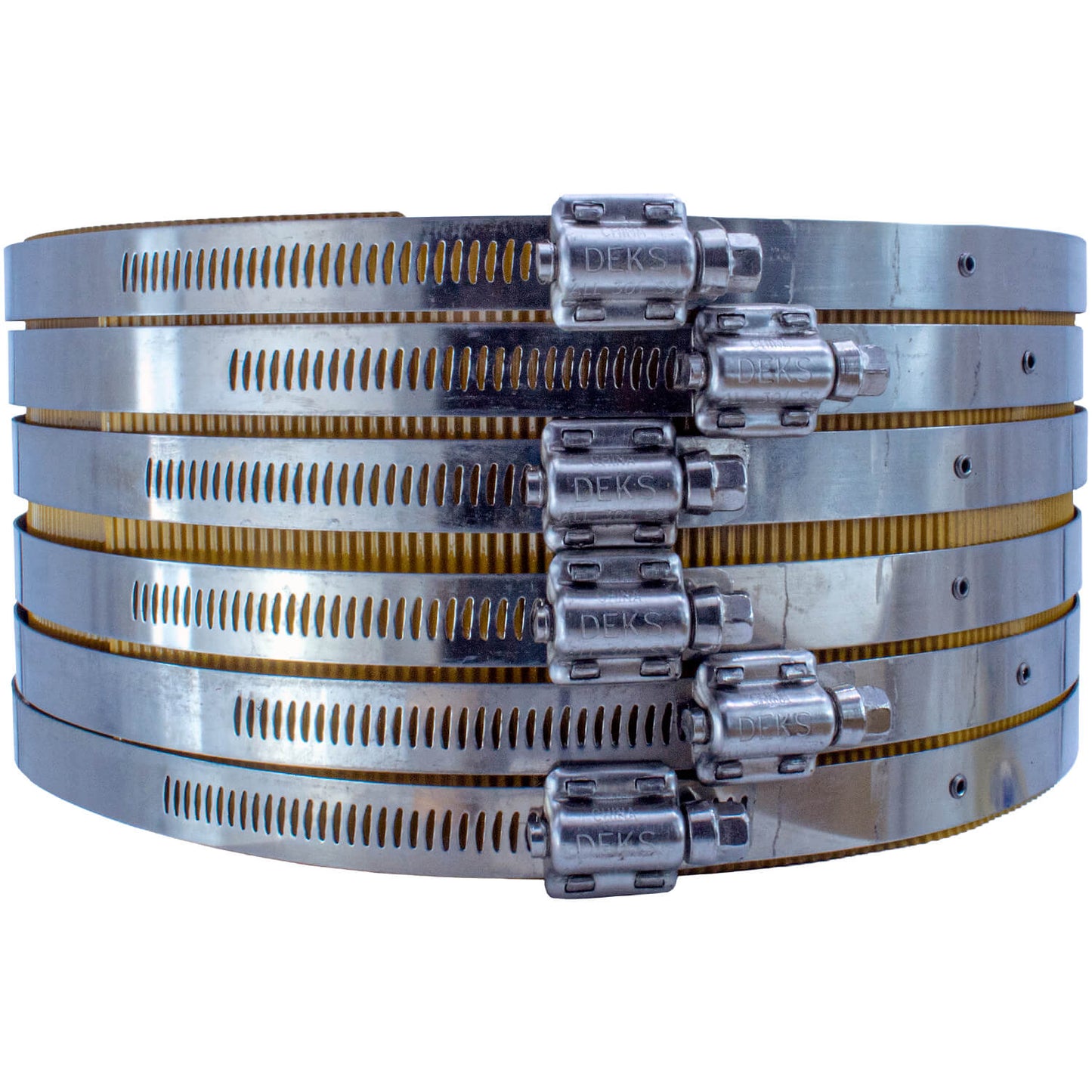

Dektite Stainless Steel Non-Shear with Gear Bands Couplers - Flexible With Shear Ring

DX1056 SR Series Couplers - Clay, Plastic, Copper, Steel or Lead to Clay, Plastic, Copper, Steel or Lead

DX1002 SR Series Couplers - For Connecting Clay Pipe to Clay or Plastic Pipe (PVC)

DXNH Series Stainless Steel No Hub Couplers - For Connecting Clay and Plastic Pipe (PVC)

✔Clay, Plastic, Copper, Steel or Lead to Clay, Plastic, Copper, Steel or Lead

✔Resistant To Chemicals, Ultraviolet Rays, Sewer Gas and and Root Resistant

✔For Non-Pressure Drain, Waste and Vent Pipes Only

✔Include and Are Not Limited to Household Sewer, Drain, Waste and Vent Piping But Also Retrofit Repairs, Roof Drains and Cut-Ins

Call Customer Service at 406-752-5253 to Inquire About Quantity Discounts

Reasons why shielded couplings are important: (1) Shear forces: Shielded couplings are made with a heavy-duty shear ring that helps the pipeline withstand shear forces and tensile stressing. (2) Pipe alignment: Shielded couplings help keep pipe alignment. Protection from ground pressures: (3) Shielded couplings are encased in a metal structure (shear ring) that protects them from the grounds surrounding pressures. (4) Cost savings: Shielded couplings can help eliminate costly repairs (5) Ease of installation: Shielded couplings can be easier to install because they require fewer stainless steel bands, which reduces the amount of tightening time.

Product Information Link Available Here

Dimensions based on Outside diameter of the pipe (i.e. 6") Coupling ID is Inside dimension of Coupler

DX1056 SR Series Couplers - SS Non-Shear Shield with 4 Gear Bands

For Non-Pressure Drain, Waste and Vent Pipes Only. The gasket is manufactured from virgin compound in which the primary elastomer is polychloroprene (neoprene). These couplings consist of a 301 stainless shield in conjunction with stainless steel clamps, secured in place by means of an affixed and floating eyelet to allow the clamps movement during tightening, allowing the band and shield to move independently. The stainless steel shield and clamps are corrosion resistant. Heavy Duty SS Shielded Coupling has been engineered join Cast Iron pipe, PVC., Steel, Copper, and tubular drain waste and vent systems. Horizontal pipe and fittings must be installed / properly braced per Chapter IV, Handbook Cast Iron Soil Pipe Institute to prevent movement or joint separation. Meets ASTM C 564 - Meets ASTM C 1277 - Meets CISPI 310 (ASTM A 888) - Meets CSA B 60 UPC / IAPMO File #4936

DX1002 SR Series Couplers - Stainless Steel Non-Shear With 4 Gear Bands

The gasket is manufactured from virgin compound in which the primary elastomer is polychloroprene (neoprene). Engineered to join Cast Iron pipe, PVC., Steel, Copper, and tubular drain waste and vent systems. Horizontal pipe and fittings must be installed / properly braced per Chapter IV,Handbook Cast Iron Soil Pipe Institute to prevent movement or joint separation. Meets ASTM C 564 - Meets CISPI 310 - Meets ASTM C1460 UPC / IAPMO File #6525 - Meets CSA B 602

Horizontal pipe and fittings must be installed / properly braced per Chapter IV,Handbook Cast Iron Soil Pipe Institute to prevent movement or joint separation

DXNH Series Stainless Steel No Hub Couplers

The gasket is manufactured from a properly vulcanized virgin compound in which the primary elastomer is polychloroprene(Neoprene). Heavy Duty SS No Hub Coupling has been engineered to provide a heavy duty, all stainless steel coupling, fulfilling the desire for a more rigid joint with the need to provide a superior sound seal, which can accommodate possible disparities in the mating of No Hub pipe and fittings. This has been accomplished by manufacturing our coupling with a heavy duty corrugated shield of ample width to accommodate additional surface bearing sealing clamps. The additional sealing clamps when torqued to 80 inch pounds, offer two important performance related installation benefits. First, the overall dimensional thickness of the clamp and shield, in conjunction with the additional width of the coupling result in a more uniformly rigid joint, with the load being supported at both the outer edge of the coupling and the centerline of the joint. Second, the additional sealing clamps provide increased surface bearing contact between the coupling and the pipe or fittings, thereby inhibiting joint movement at higher internal pressuresMeets ASTM C 564 - Meets ASTM C 1540 - Meets CISPI 310 - Meets FM 1680 Class 1 - Meets CSA B 60 IAPMO File 6525

DX1056 SR Series Couplers - Clay, Plastic, Copper, Steel or Lead to Clay, Plastic, Copper, Steel or Lead

DX1002 SR Series Couplers - For Connecting Clay Pipe to Clay or Plastic Pipe (PVC)

DXNH Series Stainless Steel No Hub Couplers - For Connecting Clay and Plastic Pipe (PVC)

✔Clay, Plastic, Copper, Steel or Lead to Clay, Plastic, Copper, Steel or Lead

✔Resistant To Chemicals, Ultraviolet Rays, Sewer Gas and and Root Resistant

✔For Non-Pressure Drain, Waste and Vent Pipes Only

✔Include and Are Not Limited to Household Sewer, Drain, Waste and Vent Piping But Also Retrofit Repairs, Roof Drains and Cut-Ins

Call Customer Service at 406-752-5253 to Inquire About Quantity Discounts

Reasons why shielded couplings are important: (1) Shear forces: Shielded couplings are made with a heavy-duty shear ring that helps the pipeline withstand shear forces and tensile stressing. (2) Pipe alignment: Shielded couplings help keep pipe alignment. Protection from ground pressures: (3) Shielded couplings are encased in a metal structure (shear ring) that protects them from the grounds surrounding pressures. (4) Cost savings: Shielded couplings can help eliminate costly repairs (5) Ease of installation: Shielded couplings can be easier to install because they require fewer stainless steel bands, which reduces the amount of tightening time.

Product Information Link Available Here

Dimensions based on Outside diameter of the pipe (i.e. 6") Coupling ID is Inside dimension of Coupler

DX1056 SR Series Couplers - SS Non-Shear Shield with 4 Gear Bands

For Non-Pressure Drain, Waste and Vent Pipes Only. The gasket is manufactured from virgin compound in which the primary elastomer is polychloroprene (neoprene). These couplings consist of a 301 stainless shield in conjunction with stainless steel clamps, secured in place by means of an affixed and floating eyelet to allow the clamps movement during tightening, allowing the band and shield to move independently. The stainless steel shield and clamps are corrosion resistant. Heavy Duty SS Shielded Coupling has been engineered join Cast Iron pipe, PVC., Steel, Copper, and tubular drain waste and vent systems. Horizontal pipe and fittings must be installed / properly braced per Chapter IV, Handbook Cast Iron Soil Pipe Institute to prevent movement or joint separation. Meets ASTM C 564 - Meets ASTM C 1277 - Meets CISPI 310 (ASTM A 888) - Meets CSA B 60 UPC / IAPMO File #4936

DX1002 SR Series Couplers - Stainless Steel Non-Shear With 4 Gear Bands

The gasket is manufactured from virgin compound in which the primary elastomer is polychloroprene (neoprene). Engineered to join Cast Iron pipe, PVC., Steel, Copper, and tubular drain waste and vent systems. Horizontal pipe and fittings must be installed / properly braced per Chapter IV,Handbook Cast Iron Soil Pipe Institute to prevent movement or joint separation. Meets ASTM C 564 - Meets CISPI 310 - Meets ASTM C1460 UPC / IAPMO File #6525 - Meets CSA B 602

Horizontal pipe and fittings must be installed / properly braced per Chapter IV,Handbook Cast Iron Soil Pipe Institute to prevent movement or joint separation

DXNH Series Stainless Steel No Hub Couplers

The gasket is manufactured from a properly vulcanized virgin compound in which the primary elastomer is polychloroprene(Neoprene). Heavy Duty SS No Hub Coupling has been engineered to provide a heavy duty, all stainless steel coupling, fulfilling the desire for a more rigid joint with the need to provide a superior sound seal, which can accommodate possible disparities in the mating of No Hub pipe and fittings. This has been accomplished by manufacturing our coupling with a heavy duty corrugated shield of ample width to accommodate additional surface bearing sealing clamps. The additional sealing clamps when torqued to 80 inch pounds, offer two important performance related installation benefits. First, the overall dimensional thickness of the clamp and shield, in conjunction with the additional width of the coupling result in a more uniformly rigid joint, with the load being supported at both the outer edge of the coupling and the centerline of the joint. Second, the additional sealing clamps provide increased surface bearing contact between the coupling and the pipe or fittings, thereby inhibiting joint movement at higher internal pressuresMeets ASTM C 564 - Meets ASTM C 1540 - Meets CISPI 310 - Meets FM 1680 Class 1 - Meets CSA B 60 IAPMO File 6525